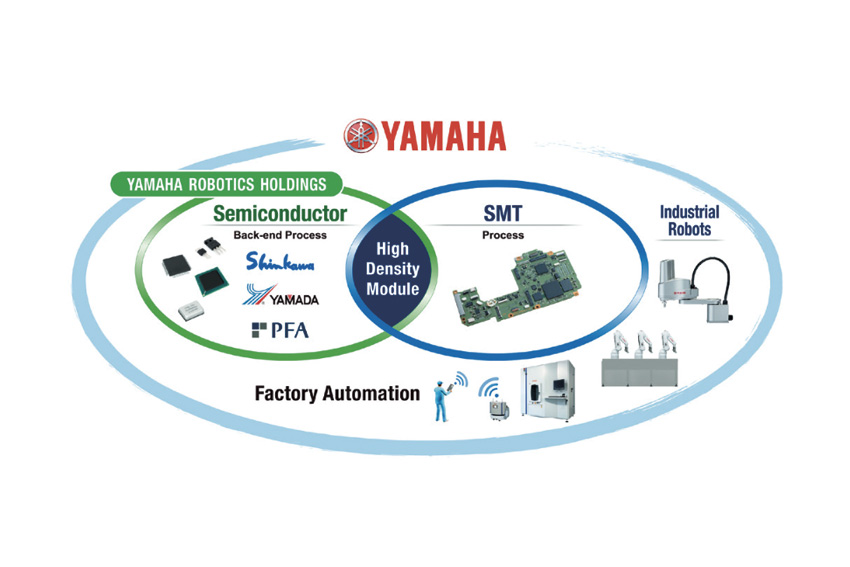

As the only company operating in the “Three Big Worlds” of back-end semiconductor manufacturing, surface mount technology (SMT), and factory automation, Yamaha Robotics Holdings solutions serves as a one-stop smart solution provider.

As our world has become increasingly digitalized, the demand for semiconductors has grown exponentially in recent years. Now, with the emergence of new Industry

4.0 technologies such as 5G/6G broadband, Big Data, IoT, cloud computing, advanced robotics and automation, that demand will continue to grow, with semiconductor manufacturers tasked with creating increasingly miniaturized components offering ever-greater power and performance.

As one of the leaders in the semiconductor industry, Japan has naturally positioned itself at the forefront of this new Industry 4.0 era, although often working behind the scenes amid increasing regional competition. Countries like China and South Korea have become leaders in ‘modular’ manufacturing -- that is assembling components to develop end-user products. However it is in the more challenging field of ‘integral’ manufacturing that Japanese companies continue to shine, with its legion of semiconductor-related manufacturers particularly strong in areas such as processing, testing and inspection equipment, back-end technologies, surface mount technologies, as well as advanced robotics and factory automation.

“There are various reasons why Japan remains a leader in the semiconductor equipment field. Japan’s experience in the semiconductor industry is quite long therefore the technology that Japanese companies have developed is quite advanced and enough to meet the demands in the market,” explains Toshimizumi Kato, Chairman and Director of Yamaha Robotics Holdings (YRH).

“For new players in the market, this modular type of manufacturing is very easy because you just assemble the parts; mobile phones and computers are created through such modular manufacturing. The integral type of manufacturing is difficult, but it is something that Japanese companies are very good at, which is evident in their technology. Large and continuous investment is necessary to be competitive in order to develop advanced technology.”

As a subsidiary of Yamaha Corporation, YRH continues to make its investment in advanced technologies based around three core areas: back-end semiconductor manufacturing, surface mount technology (SMT), and factory automation. YRH’s competitive edge stems from integrating these – what it calls – “Three Big Worlds”, which allows it to serve its customers as an “advanced one-stop smart solution provider” by offering a wide range of products and services.

“We are working on our strategy to be the No.1 one-stop smart solution provider in this industry. Right now, we are number three in global rankings in each ‘World’, however, we want to quickly integrate and provide solutions to become number one. We are hoping to achieve this within three years. The fact is that the only company that is present in these ‘Three Worlds’ is Yamaha.”

One area in which the company already holds a number one position is automotives, where the emergence of electronic vehicles has spurred increasing demand for high-performing semiconductors. “We are pretty strong when it comes to the automotive world, which is much more demanding compared to other ICT fields or communications networks,” says Mr. Kato.

“In fact, all of our products are already utilized by the Japanese automotive makers. With regards to SMT, however, we still have room to grow when it comes to sales in Europe. We are looking to expand our brand and sales on that end, while our inspection devices are already highly regarded and utilized by European automobile makers.”

“The semiconductor market is going to grow,” he adds. “Fortunately for us we already are strong in the inspection market, and moving forward I think we will be able to utilize our machinery on a tailor-made basis. The greatest strategy for us would be to see what extent we can promote our inspection devices.”

As Yamaha looks to strengthen its presence on the international market through the promotion of its advanced technologies, the company will continue to innovate and invest in R&D in order to meet the ever-evolving demands of the semiconductor industry, thus placing itself at the forefront of the Industry 4.0 era.

0 COMMENTS