Explore the insights and visions of Katsunori Matsuoka, President & CEO of Kaji Technology Corporation, as he discusses the transformative role of Japanese technology in the face of global challenges. From geopolitical shifts to the pursuit of carbon neutrality, delve into the strategies, innovations, and international aspirations shaping Kaji Technology Corporation's trajectory in the manufacturing sector.

Now is a pivotal time for the Japanese industry. Policies, like the US Inflation Reduction Act, are forcing corporations to diversify their supply chains for reliability and reduce country risks from nations such as China. Japan is known for its reliability and advanced technology. Lastly, due to the weak Japanese yen, the made-in-Japan has never been so cost-effective, meaning Japan has an opportunity to expand upon its existing global market shares. Do you agree with this sentiment? What are the advantages of Japanese companies in this current macro environment?

I share the same sentiment. Given the geopolitical and military risks associated with Russia, China and North Korea, the U.S. and other nations are actively working to mitigate these risks. I've heard that some companies are transitioning their suppliers from China to Japan or other Asian countries.

Over the past 30 years, wages in Asian countries have doubled. During this time, Japanese wages have remained the same due to economic stagnation, effectively lowering costs in Japan. Moreover, thanks to the weak yen, the cost competitiveness of Japan has improved again.

The addition of the above trends to Japan's high-level technology and quality has significantly boosted its competitiveness.

Japan is facing one of its biggest challenges -its demographic situation. It's the oldest society in the world with a shrinking population, which means that a smaller group of graduates is coming through for companies to find new workers and pass on their knowledge to the next generation. Additionally, the domestic market is also shrinking. How have you been reacting to some of the challenges this demographic shift has presented to your firm?

As we grapple with a declining population, the looming labor shortage will negatively impact our company's growth. Our unique approach involves one-by-one production, where products are tailor-made based on customer orders, constituting over 50% of our product lineup. This method demands a workforce proficient in design and production management for various coordination due to the handmade nature of our products. We aim to increase the proportion of standard products, thereby reducing the need for additional employees.

We recently established a new assembly factory in 2022, offering a spacious layout conducive to constructing a linear production line. This streamlined process is expected to enhance our production capacity without expanding our current workforce.

Even though less than 20% of our total sales are derived from global markets, our 2030 vision underscores our plan to boost international sales as part of our commitment to carbon neutrality abroad. We are exploring two avenues for forging partnerships with foreign entities. The first involves leveraging the resources of our parent company, Mitsui E&S, which boasts an extensive network through its foreign branches, facilitating the sale of our products.

The second option involves independently seeking alliances with foreign companies. For example, we can produce and export bare compressors to our foreign partners, who can install peripheral equipment and sell products related to hydrogen stations and others. We are actively searching for potential partners to support our endeavors.

What key characteristics are you looking for in a partner in international markets?

Our initial strategy involves exporting our bare compressors, allowing foreign partners to integrate peripheral equipment as needed. In the next phase, we are exploring licensing opportunities, wherein our partner companies would pay a licensing fee for the use of our technology. Consumable parts are an important element in our licensing agreements related to after-sales services. We are committed to providing our partners with a steady supply of consumable parts.

Japan aims to be a carbon-neutral society by the year 2050. Your firm has committed to this through your Kaji for Earth 2050, supporting the hydrogen supply chain. Your compressors are utilized to reduce, store, and transport hydrogen. Can you tell us how your Kaji for Earth 2050 initiative has informed some of your business operations so far?

We introduced the 98-megapascal compressor five decades ago. Over the years, we have continued our R&D and accumulated valuable expertise, positioning ourselves as industry leaders.

Our dedication to innovation allowed us to supply compressors to hydrogen stations early on, establishing us as the sole company producing reciprocating compressors. This key strength sets us apart in the market.

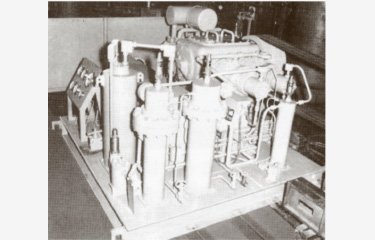

Ultra High Pressure Compressor 98MPa_HQ5A-75H

Due to the increasing use of fuel cell vehicles (FCVs) leading to the development of hydrogen stations, there's a lot of emphasis on the hydrogen supply chain in general. However, challenges persist in the compressors utilized within this chain. These challenges include the need for compressors to withstand the high pressures at which hydrogen is traditionally stored and potential issues related to embrittlement, which can compromise the equipment's structural integrity over time. How do you ensure that the compressors you manufacture can overcome some of these outlined challenges?

Since the development of our 100-megapascal compressor 50 years ago, we have amassed valuable expertise in super high-pressure compressors. Our HyKom340 compressor, for instance, stands out for its hydrogen leak-proof design, and we've also developed materials for producing parts that meet ISO 14687-2 hydrogen fuel quality. Recognizing that higher pressure can reduce the service life of compressor rings, leading to increased costs for customers, we have received requests to extend the ring's service life. Our ongoing research and development efforts are dedicated to addressing this customer need. Continuously solving challenges for our customers has been instrumental in our sustained success in the industry.

HyKom340 compressor

In addition to hydrogen stations, your products are used in other applications such as petrochemical plants, CNG production, and even PET bottle molding. Is there a specific focus on any other application you have in mind? Are there any new applications to which you would like to introduce your products?

Despite the decline in the Japanese population and the consequent shrinkage of the domestic market, we foresee a pivotal shift toward a carbon-neutral society. Our top priority will be businesses related to carbon neutrality, both in Japan and foreign markets, where growth opportunities are anticipated.

As society veers from traditional oil usage, the number of oil refinery plants is decreasing. However, there is a rise in the consumption of plastics. Even though crude oil may not be directly used as a fuel, it plays a crucial role in the processing and manufacturing as a raw material of plastics. Currently, we are receiving inquiries about petrochemical plants, suggesting that the demand for raw materials for plastics is likely to persist, at least for the time being. Furthermore, we can expect advances in technology for the production of chemical raw materials from clean hydrogen and CO2, and chemical recycling, that is, the conversion of waste plastics into chemical raw materials. This aspect will be our secondary priority.

Do you believe that Japan will achieve carbon neutrality by 2050?

Yes, I do. It is a very difficult goal, but I strongly believe in achieving it.

What do you think Japan should do to reach that target? How will your compressors help achieve that?

Importing hydrogen from overseas is not realistic due to the high transportation cost at this moment. The local production and consumption of hydrogen is necessary, which I think will be realized in the future. When hydrogen is produced locally, it will undergo compression and storage. We anticipate our compressors playing a vital role throughout the hydrogen supply chain.

In 2015, your firm was acquired by Mitsui E&S. When they made an additional investment, they became the majority shareholder in the company. What are some of the synergies that you can leverage having them as your parent company?

Mitsui E&S, our parent company, currently holds a 51% stake in our shares, establishing us as a consolidated subsidiary. While Mitsui E&S specializes in producing large-size reciprocating compressors for oil refinery plants, our company focuses on manufacturing small and medium-sized compressors. The markets served by these two entities are distinct, fostering a complementary relationship that generates valuable synergy.

This collaboration allows us to share resources in R&D and procurement, resulting in significant cost reductions across these areas. Operating as a subsidiary of a larger corporation, we benefit from collaborative efforts in R&D, human resources, sales, and production with our parent company.

Furthermore, our parent company gains a strategic advantage by expanding its product lineup to include small and medium-sized compressors, a segment it did not previously offer. This enables them to provide comprehensive compressor solutions by offering our products with their large compressors as a package. The collaborative efforts between our company and Mitsui E&S yield numerous synergy effects on the business side.

Do you have any new products that you would like to showcase?

This year, we have received an order for 12 compressors designated for hydrogen stations, consisting of two for passenger vehicles and 10 for heavy-duty vehicles. Given the rise of EVs, we anticipate limited growth in hydrogen stations catering to passenger vehicles. The market demand has shifted toward hydrogen stations for heavy-duty vehicles. In response to this trend, we are collaborating with our parent company on the development of large-size compressors to meet the increasing demand.

Following the successful development of these large-size compressors, we are contemplating introducing them to the global market.

Which country or region have you identified for further expansion? Which do you believe has the most growth potential for your firm?

Our main market for hydrogen stations would be Europe, the US, and Asian countries including China and Korea. With a strategic focus on advancing carbon neutrality, we plan to prioritize and initiate our efforts in European countries.

Imagine that we come back on a short term, two years from now, for your 120th anniversary and have this interview all over again with you. What would you like to tell us? What are your goals for this company, and how would you like your company to be seen by the international market?

Our primary focus remains on the Japanese market, which constitutes 80% of our customer base. Despite being a relatively small local factory, my vision for the next two years is to expand our horizons. I aim to see our employees actively engage in sales activities on a global scale, taking our company beyond its current boundaries.

For more details, explore their website at https://www.kajitech.com/en/

0 COMMENTS