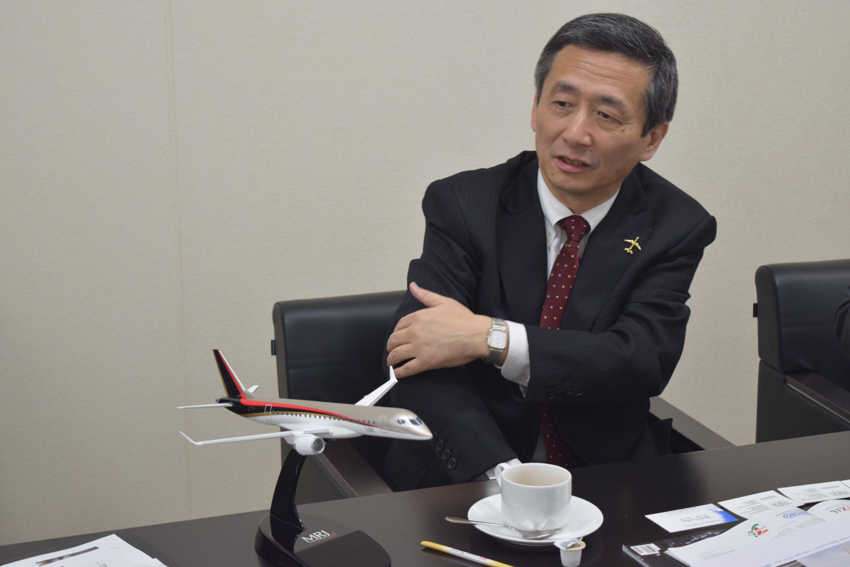

The highly anticipated Mitsubishi Regoinal Jet (MRJ) is more spacious, comfortable, and fuel efficient, and with much lower noise levels and environmental impact, than its nearest competitors. Currently undergoing extensive testing, primarily in the US, it is a testament to Japanese craftsmanship and meticulous attention to detail and quality. Hiromichi Morimoto, President of MRJ’s creator, Mitsubishi Aircraft Corporation, explains the all-round benefits the MRJ will bring, as well as the company’s involvement in developing the fastest train on Earth.

What would you say has been the impact of Abenomics on the manufacturing sector and Mitsubishi Aircraft Corporation specifically?

As you know, Abenomics has undertaken Japan’s economic revitalization. It has been a very aggressive, proactive effort to help Japan’s economy; however, this is not just for Japan’s economy. Abenomics is also helping the Japanese economy help other economies around the world. Stabilizing Japan’s economy creates stability in the world. That is the Abenomics initiative. There are three arrows to the plan. There is the financial plan, the easing of the financial burden, and the fiscal stimulus. The third arrow is private industry driven revitalization of the Japanese economy. That is where it comes to affect us so this is what I am going to focus on.

Financial stability. The first one was the easing of the financial burden on the economy. The second one has to do with financial stimulus too. Then the third arrow has to do with helping private industry to spearhead the revitalization of the Japanese economy, which is where it really affects Mitsubishi, MRJ (Mitsubishi Regional Jet). This has to do with Japanese technology, Japanese products, and Japanese manufacturing quality contributing to the economy. The MRJ will not just contribute to Japan, it will help countries around the world. It will contribute to their economic growth so we see it as playing a role. That is my understanding of Abenomics, and how it pertains to us. Try to imagine how many parts are in an airplane. A car has 30,000 parts. There are a million parts in a typical aircraft, which means that there is a lot of technology. With all these components, there is a large economic ripple. This is not just applicable to Japan. We are going to contract with outside companies. We order parts and components, and work with people around the world. In doing so, there is an economic effect that is global, not just in Japan.

One more thing regarding Abenomics. There is an initiative that involves the government and private sector working together in solidarity. What we are seeing is taking Japan’s superior technology, Japanese products, and trying to roll these out overseas. In particular, we are trying to help developing companies build their infrastructure. Prime Minister Abe himself has been meeting with leaders. When he meets with the leaders of these countries, whether it is in the energy or shipping and transport sector, he is trying to offer ideas for solutions to help these countries as well. That pertains to us as well. For Mistubishi Aircraft, we are very grateful for Abenomics, and it is a very welcome presence in terms of our business operations.

We believe that MRJ really is the perfect ambassador of superior Japanese quality and technology for the G7 summit. Can you outline for us your family of MRJ jets and what separates you from your competition in a very competitive airline industry?

Right now, we have the MRJ70 and the MRJ90. The MRJ70 has 76 seats and the MRJ90 has 88 seats (with typical single-class configuration); these two are under development. The MRJ100 is something that we are discussing, but we are conducting market research. We are going to deliver the MRJ90 first, then deliver the MRJ70, then we are going to consider developing the MRJ100.

Our primary competitor in this space is a Brazil-based company, Embraer. In terms of advantages or characteristics of our aircraft that separates us from our competitors, there are three. The first is efficiency, which basically comes down to fuel economy. The second is environment or green component, which is environmentally friendly. The third is for the airlines—it is a very economic platform to fly; it is profitable for them because it uses less fuel.

In terms of the first characteristic we are going to use, we are using the Pratt & Whitney engine; the US-based engine maker. It is their newest engine. To put it simply, this makes us 20% more competitive than our rivals’ top technology, so it saves fuel and has better fuel consumption. This means more profits, which is better for our customers. Then in terms of other technology—our aircraft, our aerodynamic technology—we have outfitted with the best technology, which is slim and very aerodynamic. By employing advanced aerodynamics, the MRJ’s design is a major contributor to its industry-leading fuel efficiency and noise reduction.

At the G7, one of the main themes is sustainability, and green economy. This is obviously a very important topic. MRJ is designing the most advanced airplane in the world in this regard. Is this the future of fuel efficient and environmentally friendly air travel?

One thing that I want to mention is that it is not just good for the customers, in other words, our customers, the airlines, but also the passengers that will fly on the plane. The primary reason behind this is the way it is configured, and its spaciousness. It is more spacious than conventional jets in the same class. There is more head clearance and more elbowroom. In terms of legroom, it is also superior. The overhead has a lot of space so it can accommodate the largest piece of luggage that is recognized by IATA. Basically, passengers will not have to check in luggage because the plane can accommodate it. There is a lot of space, and this will make traveling on our planes more of a pleasure for our passengers.

In terms of the environment, there are two main things I want to highlight. One is the noise level, and the second is the exhaust. In terms of noise, our competitors have a level over 70 or 90 decibels. MRJ’s noise footprint is at 40db. This is good for highly concentrated residential areas where the residents will be very grateful. In terms of emissions, the standards are set by the ICAO. The MRJ’s exhaust emissions are much lower than their standards. This is a green aircraft, and is environmentally friendly and sustainable.

What is the timetable you’re seeing to roll these out into operation?

We made our first flight in November 2015 and the first delivery is now scheduled for around the middle of 2018.

Your jet is also an amalgamation of American and Japanese technology. As well as your partnership with the Pratt & Whitney engines, Mitsubishi Heavy Industries works with three engineering bases in North America. Is this the ideal candidate for a partnership between American and Japanese technology? Do you feel like an ambassador of these two worlds coming together?

This is very much a Japan and US project. It is being made in Japan and is going to have a ‘made in Japan’ label on it, but it is substantially a joint developed project in the sense that we work with a number of US companies for the core components. We talked about the Pratt & Whitney engine, that is one. There is the UTC Group. In terms of the avionics, we are going to incorporate Rockwell Collins flight decks. We work with many US companies for the core components. The reason behind this is that these partners have very esteemed track records. They have great technology. They are also reliable, very trustworthy, and we want to use those components of systems in our plane. That is one sense of how it is a US-Japan project.

Another sense is that we are conducting the flight test campaign and in Japan there are many restrictions in terms of when and where you can fly, and the limitations of the airspace. The weather is also an issue. In North America, it is very flexible at one of the airports not far from Seattle.

From the summer to the fall, we are going to take four aircraft over to Moses Lake in Washington state, and we are going to conduct out flight tests. For example, we are going to do a very high frequency which they call a clearance C rate, the Clear ratio.

There is a clear weather ratio, and that is 95%. There is a higher chance of the weather being clear there than in Japan, so it is beneficial in terms of weather as well. Basically, we are going to have concentrated testing over there. The people in Washington state and Seattle have been integral and very helpful to our project.

A third point that also relates to how this is a US-Japan partnership is our 407 orders.

Three hundred and forty (340) orders are from the US; so 80% of our orders are essentially from the US. The bulk of the aircraft that we deliver will probably be flying over the US air skies, the passengers will probably be the people that are US people or live in the US.

There are two ways to distribute your airplanes. You can sell them or you can lease them. I read a great quote where you said, “We will take the offensive in the leasing industry.” This is a top priority, and you already have many orders. Can you outline your strategies in the leasing sector?

At the Singapore Airshow, we announced a LOI (Letter of Intent) with Aerolease for the 10 firms and 10 options.

Leasing firms make up 40% of the market. Sixty percent of the market is airlines—so, the leasing market is significant. With lease orders, the leasing companies look at the plane as an asset. They do not want to buy something that is going to depreciate. They want something that has value and the fact that they are interested in our aircraft shows it’s a metric, a barometer for showing our aircraft’s value.

After the leasing companies receive delivery of the airplane, they need to contract with airlines to use it. Only then is the leased MRJ—the plane—actually used. We are going to work together with leasing companies to approach airlines to assist with their sales and promotion because leasing is an alternative for customers. It can be one that makes them very satisfied, and very happy with business. So leasing, not just selling, is another sales area that we can pursue. We believe it is very significant.

One of the things that separates Mitsubishi Aircraft Corporation from its competitors is your corporate culture. It’s very Japanese, and is almost an obsessive focus on quality, efficiency and superior technology. Can you outline how this translates into day-to-day business and how it’s going to separate your jet from the competition?

Mistubishi Heavy Industries is our parent company that has been making Japanese aircraft for a long time before World War II; it made fighter jets like the Zero, for example. They were renowned for their technology. We have long been affiliated and have made superior aircraft, but after World War II making these types of aircraft was banned, which lead to a hiatus in aircraft construction.

Mitsubishi Heavy Industries had two departments. One is the commercial and the second is the military. In terms of the commercial, there is the YS11, which was a commercial aircraft that we made more than 50 years ago. We were the primary contractor. We designed and developed the aircraft; unfortunately, production ended after 180 aircraft. We also created the MU2, and created around 300. This is a business jet that carries 7 to 8 passengers. This is another achievement. This is the legacy that we carry.

In terms of working with Boeing, we were a tier one contractor and helped with projects that worked on the 737, 777, and 787. We not only made parts, but also major components including the fuselage panels and the main wings. We are a supplier, and we worked on design.

Our second point is military. In terms of the military jets, we have licenses for US technology in order to design and manufacture components and aircraft. Mitsubishi Heavy Industries has been the primary contractors for aircraft including the F86F, and further on down the line there are other jets. We are also involved with the F2 helicopter, which will be coming. In addition, we are producing the F35 with advanced military technology.

Both military and commercial technology are fused and crystallized in the MRJ.

Just like the Shinkansen at the 1964 Olympics, we really believe that the MRJ is the ambassador and the embodiment of Japanese superior technology and quality for the G7. Do you feel yourself as an ambassador for Japan’s economy as these world leaders are here in Japan discussing global events?

The 1964 Tokyo Olympics was when the Shinkansen began to operate. Now, we have the Olympics returning to Tokyo in 2020, so on a similar note there is the linear motorcar we call the Maglev. As you may know, it floats. It operates based on resistance and magnetic propulsion. They are just starting to work on it. Actually, the front carriage for it is something that we have been tasked with developing. It has to have a very narrow wedge like a nose to make it aerodynamic.

In regard to the Olympics, it would be very nice if we would be bringing the Olympic torch to Japan using MRJ technology. This is not anything that has been settled on, but it is something for which we are hoping. In the 1964 Olympics, we brought the Olympic flame using the YS11 from Okinawa. They relayed it up the coast using the YS11 to do it. The upcoming Olympics is another opportunity for MRJ to show its technology. We talked about the G7 Summit, and we will be displaying the MRJ there so everyone can see it. In addition, we are going to continue to attend airshows. There is the Farnborough Airshow outside London this year so we are going to keep promoting our product, and the craftsmanship to tell people around the world about what we are doing.

There are certain parts of the plane that can be produced by robotics; however, there are some things that we cannot automate and have to be handmade. For example, there are narrow spaces we have to go into to equip the aircraft with piping for cabling—all this work entails fine craftsmanship. The Japanese are very adept in this type of intricate work. These details really reflect the Japanese people’s craftsmanship. If you are making a massive aircraft like Boeing, you can automate production. You can use robots, but our craft is narrow and different, and so reflects the strength of Japanese craftsmanship. Also, we were talking with the leasing company Aerolease. They actually came to see our plant to check our production process and assess the quality of our products. When they saw it, they basically said that they were confident in our process and our aircraft, and saw its ability to maintain value. This confidence led them to place the order for Japanese technology.

0 COMMENTS