With its accumulated know-how and expertise, Kurihalant aims to be the firm that can provide total solutions in energy engineering

As an island nation, 95% of Japan’s energy needs are currently fulfilled through imports. The Kishida administration recently revised its basic energy plan, making renewable its priority source of energy was increasing the share of nuclear power. What is your take on the energy mix you feel is best for Japan?

My personal opinion is that nuclear power should return to become the core of Japan’s energy mix. To achieve this. First, we have to focus on reutilizing and recommissioning the existing nuclear power plants safely and efficiently. At the same time, we have developed and constructed an innovative next-generation reactor and also accelerated reprocessing, decommissioning and the final disposal process.

As for renewable energy, we know that the most efficient one currently is offshore wind power generation. For this form of power generation, many challenges need to be overcome. Japan is located on the path of typhoons and the country as a whole is vulnerable to natural disasters like earthquakes and tsunamis. That means that any technological advancements need to be robust enough to survive said natural disasters. We also have an issue with sea depth, with Japan being located in deep sea waters, so we have to figure out the best construction method.

I believe that the ideal situation is a combination of those two energy sources, however, the downside is that both of these energies are not flexible, especially to sudden changes in demand. Consequently, we have to elevate the technologies related to power storage so that we can cater to requirements and add flexibility to these power sources.

Having said that, achieving these technologies to enable an ideal energy mix will take time. As such, the country cannot stay idle while policymaking and technologies advance. Practically speaking, it is, therefore, necessary to continue the operations of thermal power plants by using efficient liquefied natural gas (LNG) and fired gas turbine combined-cycle (GTCC) to which we developed technology to be able to combust hydrogen mixed with LNG and also develop ammonia and coal mixed combustion in coal thermal power plants. These efficient technologies will allow us to optimize the production of thermal power plants.

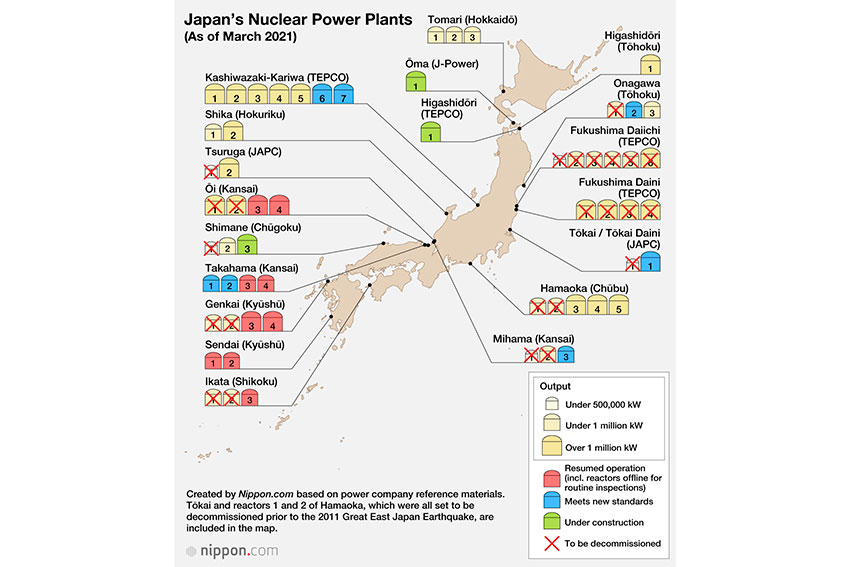

In 2011 before the Tohoku earthquake, Japan had 54 nuclear reactors but as of January 2022, only 10 have been restarted and 21 have been decommissioned. However, the Japanese government has plans to have nuclear form at least 20% of its energy mix by the year 2030. As the share of nuclear energy within Japan’s mix is set to increase, what opportunities does this present for your firm?

Currently, we have a direct consignment with plant manufacturers for the reoperation of nuclear power plants. We are currently focused on plutonium reprocessing and reuse facilities in Aomori prefecture. As for the nuclear power plant recommissioning in Hokkaido, there is a plan in place and we want to shift more toward a boiling water reactor (BWR) process from PWR since PWR recommissioning is already in progress and we can utilize our technology, which we learned from PWR projects.

What technologies are you developing to increase the storage and transmission efficiency of intermittent energy sources?

We do not plan to develop high-performance or next-generation storage batteries. Rather, we rely on material and battery manufacturers. Our focus is on operating storage facilities once our customers decide to embed them within their power generation scheme. While we are not a large-scale enterprise, we have grown into an integrated power generator and distributor solution provider. We currently operate a solar power generation plant as well as small-scale hydro and biomass plants. The next step we are trying to achieve is the combination of our current facilities with storage ones. We also want to increase the efficiency and the distribution of our existing plants.

Solar power and biomass power generation are supported by the Japanese government’s feed-in-tariff (FiT) scheme, however, once it stops, there becomes a question of what the future will be. Having storage technology would be a powerful and viable option in a future where FiTs may not exist.

FiTs were introduced in 2012 to support the development of renewables. In recent years, the government has slowly started to lower the support granted through the FiTs. This has led many critics to question whether the Japanese renewable energy sector would be able to survive without them. Do you believe that FiTs are still necessary? What steps must be taken so that the renewable sector is not reliant on the FiT system to be competitive in terms of pricing?

In our current market environment, a large-scale biomass plant is economically viable without the FiTs. That being said, it also depends on the alternative that you compare the plant to. For example, if you were to set up a large-scale biomass plant against the rising oil prices, it becomes economically viable. Inversely, if you were to take the baseline of the pre-Fukushima times, then obviously it would not be economically viable.

By not comparing itself to international rates, Japan can sustain itself using large-scale biomass power plants. However, small-scale biomass power plants are not economically viable without the FiTs, and we are fully aware of this because we are a small-scale biomass operator.

For solar panels, it is important to increase the power generation efficiency. Having said that, one of the limits of solar power is the hours of sunlight it can capture. Despite the advancement of technology, there is still that huge limitation. Through technological innovation, we may be able to double the current rate of power generation, but I believe that there is a limitation we could achieve.

We do see a silver lining in hydropower. Currently, 10% of our total energy is generated via hydropower. That number could be increased to 20%, and while that may be a high target, there are many locations where we can install small-scale hydropower plants. There are many challenges in pursuing this project. For these projects to advance, one must balance the right of governance of the Agency of Forestry as well as the local government entities that control the rivers. Additionally, you might have local associations of fishermen that use the river for their place of work. It requires an understanding of local communities. While that is not a big hurdle by itself, many lengthy processes need to be completed to achieve the installation of a hydropower plant.

Japan is located on the Pacific Ring of Fire and is blessed with various geothermal resources. However, the share of geothermal energy in the Japanese mix is extremely low. How do you explain this paradox?

My personal opinion is that the popularity and amount of hot springs and onsens limit the development of geothermal energy. Once you start geothermal generation, you have to dig deep to gain access to the waterline, so it is difficult to gain an understanding of a local community that relies on onsens.

From a technological standpoint, Japan is capable of developing the technology and materials needed to sustain the excavation of the tectonic plate down to the mantle. If it were to do so, Japan would have the chance to gain continuous sustainable energy. As with solar, wind, and hydro, local communities have so much power over the creation of such plants, and it can be a huge hindrance to the advancement of such renewable sources of energy. The Japanese government is not able to politically intervene in that area, making matters even more difficult.

Japan’s power grid suffers an annual energy loss of roughly 5% during transmission, which equates to the annual production of about five nuclear power plants. We also know that your firm has conducted research into DC superconducting power transmission systems. Can you go into more detail about how the superconducting power transmission system can help reduce or even prevent this power loss?

Our company is involved in the development of DC superconductive electric wires and electric cables. Making the cables themselves more energy efficient is important, but at the same time, you have to think of the overall picture and the placement of the generator relative to the end user. With the current nuclear power grid, we are seeing that plants are located quite a distance away from each other. By shortening this distance, we could increase energy efficiency and prevent loss of energy. Planning the generation method as well as the placement of generators with the user in mind is necessary.

What I envision is placing factories and mass energy-consuming facilities close to nuclear power plants, whereas, in urban areas, you would have smaller power generators with different energy sources. At the same time, it is important to increase energy transmission efficiency through the development of next-generation cables, such as our DC superconductive cables.

Your company has been involved in the construction of research facilities, including RIKEN’s Super Photon Ring – 8 GeV, also known as SPring-8, one of the world’s largest synchrotron radiation facilities, which is capable of producing the world’s highest-performance of synchrotron radiation. Can you tell us a little more about your work in the construction of this facility and how you got involved in this project?

The SPring-8 project is a synchrotron radiation facility in Hyōgo prefecture. We were not directly involved in the construction of the SPring-8 facility per se but in the installation of the SPring-8 Angstrom Compact free electron laser, which is also known as SACLA. SACLA is an X-ray free-electron laser (XFEL) embedded in the SPring-8 accelerator and synchrotron complex. When it first came into operation in 2011, it was the second XFEL in the world and the first in Japan. We were assigned to the installation work of SACLA directly from RIKEN, and we subsequently got a mainteance business contract. Based on this experience, we got a business contract directly from RIKEN for the construction of SACLA as well as continued maintenance.

There is a plan in place to construct the next generation of SPring-8 in the next three or four years and we look forward to being involved in that new project. Currently, we are also involved in the construction project for the next-generation synchrotron radiation facility by Tohoku University in their compound in Sendai.

Your firm has relations with many academic institutions. Are you looking for any partners internationally when it comes to development or construction projects?

Overseas, we have three subsidiaries located in Myanmar, Vietnam, and Thailand. Myanmar actually has the longest history. If we go back to the year 1970, it was the year of the first-ever Osaka Expo. It was also the first year that Japanese nuclear power plants started operations. In 1970, we dispatched our engineers to a US company called Gilbert. The US designed Japan’s first nuclear power plant, but for the second and third plants, Japanese personnel were sent in the 1970s to Gilbert to learn how to design and construct next-generation power plants. The founder’s theory was not only to be involved as a constructor for power plant generators but also to focus on the technical aspects of the work. This allowed us to be involved in the design phase.

This elevation of technical capability was done thanks to this US company and the founder always felt gratitude towards them. He was especially grateful that Gilbert allowed engineers with no knowledge or firsthand experience to be involved in learning about design. The founder wanted to pay back his gratitude to them, but Japan would have never been able to pay back the US with technology, so the founder decided to go to Myanmar and contribute to the local community there.

At the time Myanmar was called Burma, and Burmese people have a deep affiliation with the Japanese. There is actually a famous novel by Mr Michio Takeyama called The Burmese Harp. Burma was well known by the company too, and we went there to give technical training to local people and to create new opportunities. This was our way of paying back the world for the chance it gave us. Through this Myanmar project, we now have a base in Vietnam for 3D CAD engineering.

Thailand is our latest development and the purpose of that base is to manufacture container packages. This container package is not for transportation. Rather, it is used in thermal power plants as a case for control boards and control-related devices, such as starters. First, you place the control device inside the container. You can then place each container side by side and remove the walls to connect each unit. Our container packages are used in many Thai and Japanese thermal power plants.

We saw in our research that your company provided vacuum pumping systems to a series of Large Helical Device (LHD) projects.

This is more of an order-based project. On a similar level, we are currently participating in the development of next-generation nuclear power plants, especially with our involvement in atomic cases for nuclear fusion.

Moving forward, are there any other countries or regions that you have identified for further expansion into?

We have had our overseas business since the 1970s and have been involved in many large-scale projects, mainly as a constructor. In some cases, we have acted as a supervisor for the actual constructors or in the role of technical engineers. As a supervisor, we are involved in an airport construction project in Papua New Guinea.

Our current focus is on renewable energy facility construction and installation, mainly centred around hydropower. Since we have the ability to do tuning for control boards, we expect to see an increase in overseas projects for hydropower plant construction through Official Development Assistance (ODA).

Are you looking to diversify the number of projects that you have internationally?

Yes, we have a big vision for overseas expansion, and to do so, it is important to train and increase our human capabilities. Currently, resources are scarce, so we are now emphasizing strengthening our human resources for overseas expansion. Currently, the core of our capabilities is in mechanical and electrical installation. Looking at the future, we seek to expand our knowledge to offer fully integrated plant construction services. By combining construction with civil engineering, transportation, and other installation technologies, our goal is to become a comprehensive solution provider.

Imagine that we come back in five years and have this interview all over again: what goals or dreams do you hope to achieve by then?

When I became the president three years ago, we formulated a 10-year goal which we call the F10. The first three years; the second three years; and the final four years each have specific goals. If you come back in seven years, we will be completing our final phase and our target is to increase our employee count from 900 people to 1300. Additionally, we plan to increase our overall profit by 1.4 times the current amount.

We are not planning to add new business fields. Rather, we want to focus on strengthening the current business activities that we have and on increasing our overall capabilities by acquiring new projects. To do so, oversea expansion is one of the core pillars that we want to pursue.

Furthermore, we seek to change the image of our company. Kurihalant is famous in the industry as an electrical instrumentation company. Looking at the future, we seek to elevate our branding to be recognized as a holistic service provider for mechanical, construction, and comprehensive works.

My ultimate goal is to make my employees feel proud of working for Kurihalant. As such, I believe that becoming an integrated service provider will also serve to make our employees proud of the company they work for.

Interview conducted by Karune Walker & Antoine Azoulay

0 COMMENTS