Daido is a proposal-type mechatronics trading company which carries out conception and introduction support that goes from a single robot to complete robotic systems with a consistent realized method, including their Robot Exhibition Hall where they conduct seminars that fully demonstrate the robot technology and functions that are constantly evolving. President and CEO Sadao Yamada talks to us more about the automation solutions Daido is able to provide, their unique position in the industrial evolution, and their upcoming projects.

In the last few decades, Japan has seen the rise of regional manufacturing competitors, such as Korean, Taiwan and China. Nevertheless, Japanese firms have maintained their leadership in niche B2B fields. How do you explain that Japanese enterprises were able to maintain their leadership despite this stiff price competition?

There is no doubt that those countries are replicating Japanese manufacturing processes, and in most cases, doing so at lower costs. On face value, people may wrongly think that the products they manufacture are similar, both in terms of quality and functionality, to what we do here in Japan, but honestly, it is simply not at the same level.

In the realm of robotics, a large number of market-leaders are located in Japan. These firms dominate niche industries, especially in the field of industrial robots. The functionality and quality of the robots they produce is nearly impossible to copy.

This scenario is also exemplified when one observes the difference between the Japanese sword, the katana, and the Chinese weapons that imitate it. While it is possible to copy the shape and the appearance of the katana, the sharpness is impossible to do so. When one tries to cut something, they will notice the difference between both swords: they won’t need to move the katana with much force; a slight movement of the wrist will be enough to create a perfect cut.

I believe that the most significant difference between Japan and other countries is that Japanese people are dedicated individuals who put their heart and soul into everything that they do.

When this is applied to engineering, it allows for the creation of technical marvels. The people who invest in their manufacturing power devote themselves to their products. To reach that level of knowledge, they focus on one particular feature or product for decades in an attempt to reach perfection. The katana is a vibrant example of such commitment. These swords are considered a true piece of art, are exhibited in some of the world’s most prestigious museums and can cost hundreds of millions of yen.

In the next fifteen years, one out of three Japanese people will be over the age of 65, making it harder for seasoned workers to pass their knowledge to a decreasing pool of young graduates. What challenges does Japan’s demographic shift pose and how do you plan to overcome them?

This phenomenon is not only occurring in Japan. From China to Northern Europe, other countries are face this issue. China lifted the one-child policy for that precise reason.

While factory automation (FA) can provide an answer to some of these problems, an even greater solution must be provided. Next month, we will be opening an automation showroom in the Mikawa area where people can see how FA is taking place.

Regarding white-collar workers who say robots will steal their jobs, we have to remember that during the industrial revolution, workers were opposed to industrialization and to the implementation of machinery. Years after however, they realized that the industrial revolution made their tasks safer, easier and shorter.

Robotics is the next natural step in the industrial evolution, and such changes are not uncommon. Decades ago, horses were used to move around, and they were replaced by combustion engines. Similarly, robotics is bound to play a greater role in our daily lives, and it will allow people to decrease the amount of physical labour required to live.

What impact has the proliferation of DX technology had on your business?

Through the implementation of IoT, Big Data and AI technologies, robotic companies have been greatly impacted by digital transformation. Because we conduct our business with them, we have been consequently affected by it too. We frequently talk with the representatives of robotic companies to understand the new technologies they are integrating. By maintaining communication, we can walk together on the same path. In turn, this allows us to provide the best solutions to our clients while ensuring that we can adapt to the changing expectations of customers.

Next year, DAIDO will be celebrating its 75th anniversary, could you highlight some of the key milestones of the company’s history?

Three people established the company. One of them was my father, so the history of the company is like my personal history. These three individuals were the only employees at the time, and they began by selling small bearings. They went from selling bearings to pillow blocks in one year, and that was the first milestone of the company.

Business wise, many things needed to be done. DAIDO started as a small company of three employees. Today, we employ more than 1000 individuals.

The first reason for this growth was our ability to understand what the best commodity would be, and then to approach the top sellers of such products. Today, we sell most of FANUC’s products on their behalf. We do not limit ourselves to just selling the robots, rather, we also sell their engineering solutions too. With over sixty specialized engineers, our company is responsible for sharing the specificities and functionalities of robots to companies that want to purchase them. To understand our role in the industry, you must consider that robotic companies do not explain to their customers how to best utilize the robots they produce. While large firms such as Toyota and Honda have their own in-house engineers that know how to handle and install such robots, other companies do not have that capability. That is where we, DAIDO, come in. We supply Japan’s leading robotic systems to manufacturers by showing them how to install, operate and utilize FA tools.

In 2016 you opened Daido Robot Exhibition Hall in order for people to ‘watch, try and study robots.’ Why do you think it was so important to open this kind of Exhibition Hall?

We work with FANUC, EPSON and DENSO. These companies supply their products and items, but few engineers know how to properly use their robots or integrate their systems. As such, our sixty engineers integrate the robots and machines, assemble them in a system, and then supply that system to customers. While robot makers conduct the manufacturing, the proposal, installation and conditioning is actually run by DAIDO.

To give you an example of our work, Japan’s largest housing construction companies, produces prefabricated houses and house-parts in a factory. To engineer such a factory, we integrated and installed the correct robots and FA tools along their production line.

At DAIDO, our expertise allows us to provide integrated FA systems that encompass industrial robots, machinery and control systems. Using a robot as an individual item simply does not make a lot of sense. The power of robotics is to integrate it with other machines; to a large extent, it is like connecting the dots between the items and the factory as a whole. Based on that need, DAIDO is the best robot system integrator in the world.

Since we established the exhibition hall, several goals have been reached, but sales have slowed due to the pandemic. However, in the last few months, we’ve received orders from customers from various industries. The orders we receive are not for ‘robots’ only, rather, they are for a FA system that integrates robots and machines with the factory.

DAIDO assists companies present in a variety of fields, including construction, heavy industry, food and cosmetics, amongst others. How are you able to understand and cater to the needs of companies from such diverse industries?

We are Japan’s leading robotics system integrator. With that fame, when customers research who can prepare the right system for their need, they automatically find DAIDO and they contact us. Interestingly, we do not look for customers, rather, they come to us and test the robots thanks to our showroom, then they place orders.

What has been the impact of the COVID-19 pandemic on DAIDO?

The coronavirus does not affect robots, only people. As such, we have not seen any drastic effects because of COVID-19. Due to stay at home measures, remote control technologies have been increasingly introduced in factories. In response, we have adapted some of our client’s systems to be controlled remotely. Nowadays, many factories have been affected by the pandemic, resulting in a shortage of parts and delayed deliveries.

What is the role of collaboration and co-creation for your company?

No matter how excellent robots are, they cannot fully replace humans. As robots are sold in particular areas and industries, robot manufacturing companies often focus on supplying to one specific sector. FANUC and Kawasaki, for example, are great for the automobile industry. Other companies might be making robots specifically catering to the needs of one sector. No matter the industry they seek to cater to, at one point, they all go through DAIDO. We are the number one proposal-specialized mechatronics trading company that connects industrial robots with manufacturing companies. At DAIDO, we can cater to the necessities of any sector; we never discriminate amongst manufacturers. All robots have a proper function and our job is to show and explain to manufacturers how to best utilize each function of each robot.

DAIDO has been present in Shanghai, Thailand, and most recently, in the United States. When looking at the future, could you tell us what markets are key for you?

We bought the distribution rights of an certain company’s products last December and today, we supply their pottery products to the USA. Our operation in Chicago was set up for distribution purposes, as well as support for FA. Many customers in Japan are expanding and already have factories in Illinois or Texas, for example, so they requested us to set up in the US and support them. First, we bought the distribution rights for the pottery service, then we supplied the FA system.

Currently, we are mainly focusing on the US, China and Thailand; going to those three countries were request from our customers. International automotive companies have factories in Thailand, and several of our customers also have factories in China and the US. Thus, we went there mainly to support them.

As a robotic system integrator, we are focusing on penetrating the markets that our clients are expanding into. Like I’ve said before, the manufacturers only supply the parts or robots, and end users often don’t buy them from the robot maker directly. Because they do not know how to best-use these robots, they come to us, be it in Japan, Thailand or the USA, and we provide them with a fully integrated robotic system.

The old-fashioned way of doing things was to procure items all the way from Japan. Currently however, it has changed to local procurement and solutions provided by companies with local presence. Japanese companies used to conduct design activities in Japan, but now, by using the internet, they can design from all around the world. Today, a Japanese engineer located in the USA can design a product that will be assembled in Thailand with Chinese-made parts. This new paradigm forces us to expand our sales internationally.

Looking at the next five years, what are some key targets that you are looking to achieve?

We want to double our sales from the current 100 billion JPY to 200 billion JPY. To do that, we will continue to provide robots not as a unit, but as a fully integrated system. To give you an idea as to our business model, a project that requires us to install a full system costs around 100 million JPY. This unique business model is difficult to replicate.

As a robotics integrator, we are proud to see that the solutions we provide allow people to reduce the amount of difficult physical work required; we are proud to see that our FA systems allow factory workers to share more time with their loved ones. The purpose of robotics is not to replace humans, rather, it is to liberate them by reducing the tasks and work time required of them. In the future, I foresee and hope that production lines will not be reliant on intensive human labour.

What vision would you like to leave at DAIDO for the next generation of company executives?

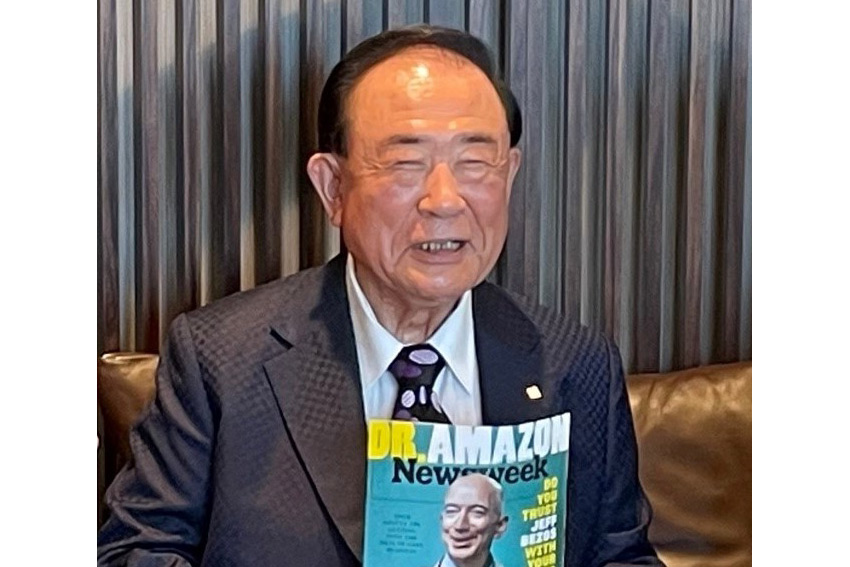

I actually wrote a book that is meant to be read by the people who will take over the leadership of DAIDO. Most importantly, I want my successors to understand what the company’s contribution to society is. The goals of industrial robots are to simplify human labour, and by extent, to contribute to society. This has been the philosophy of the company since establishment and it has been the driving force behind the successes that we have had. At DAIDO, our goal is simple: it is to contribute to the betterment of people’s life through robotics.

0 COMMENTS